Stringent drinking water standards for constituents like chromium, arsenic, volatile organic compounds, and nitrates, combined with continually higher demand for groundwater resources have led to the need for more efficient and accurate well characterization. Many wells are screened across multiple aquifers to maximize groundwater production, and since these aquifers can have different water qualities, the water produced at the wellhead is a blend of the various water qualities. Furthermore, the water entering a well may not be distributed equally across the screened intervals, but instead be highly variable based on the transmissivity of the aquifers, the depth of the pump intake, the pumping rate, and whether any perforations are sealed off due to physical, chemical, or biological plugging. By identifying zones of high and low flows and differing water qualities, well profiling is a proven technology that helps optimize operational groundwater production from water supply wells or remediation systems. This frequently results in increased efficiencies and reduced treatment costs.

Well Profiling 101

By accurately defining groundwater quantity and quality, dynamic profiling provides the data needed to optimize well designs. Conventional exploration methods frequently rely on selecting well screen intervals based on performing and analyzing drill stem tests for one zone at a time. There is also considerable uncertainty associated with analyzing geophysical logs to define flow and TDS concentrations in specific zones. Moreover, these analyses cannot provide estimates of concentrations for many chemicals of concern to water use. In addition to the limitations on the data they provide, drill stem tests are relatively expensive and time-consuming. Using dynamic flow and water quality profiling, the transmissivity and water quality can be determined for multiple production zones in a matter of one to two days. It also allows the location and size of the test intervals to be adjusted in the field, based on real-time measurements. When flow and water quality information is collected at the appropriate vertical resolution, the optimal combination of productive zones can be determined to achieve the desired flow rate and water quality to meet specific water supply needs.

Dynamic well profiling can be used to characterize many different types of groundwater wells for a variety of applications and industries. For municipal wells experiencing water quality issues that require action before the water can be used, profiling is used to adjust groundwater withdrawals, thereby reducing well head treatment costs. In support of agricultural operations, dynamic profiling can help avoid the pumping of low quality groundwater which can increase a well’s operational lifetime and avoid the costs of drilling new wells. It can also prevent the buildup of salts in soil as a result of irrigating with low quality groundwater. To provide groundwater for the industrial sector, properly profiled wells offer improved pump performance and working life by reducing total dissolved solids (TDS) and other impurities. Well profiling can also be used to optimize groundwater remediation activities. For instance, pump locations in groundwater extraction and treatment wells can be optimized to extract water from targeted zones and minimize treatment volumes.

Well Profiling Techniques and Uses

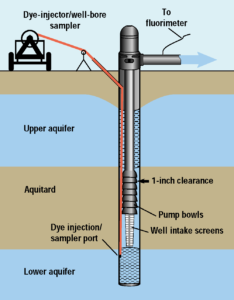

Using technology called the “Tracer Pulse Flowmeter and Depth-Dependent Sampler”, zonal contributions of flow and chemistry throughout the perforated section of a well are determined simultaneously while the well is pumping in full production mode under steady-state conditions. Minute amounts of NSF 60 tracer, approved for use in potable drinking water systems by the National Sanitation Foundation, are injected at varying depths in a well. The return rate of the injected tracer provides data that we analyze to determine flow dynamics throughout the well.

Water quality and chemistry are also essential data for effectively managing aquifer assets. Rigorous standards for trace levels of contaminants such as chromium, arsenic, uranium, and nitrates require precise and accurate sample collection. To profile water chemistry, we use a system that integrates a low-flow sampling pump, inert nitrogen gas, and flexible tubing to take depth-specific samples. The system can operate during static non-pumping or steady-state pumping conditions.

Dynamic flow and chemistry profiling is used to:

- Determine pathways of water migration into a well

- Determine mass transfer of contaminants throughout the well

- Delineate flow contribution zone by zone along the screened section of the well

- Delineate flow velocity zone by zone along the screened section of the well

- Delineate zonal percentage contribution along the screened section of the well

- Reduce or eliminate dependence on expensive treatment technologies

Examples of Well Profiling Solutions

The INTERA/BESST Team’s expertise in well profiling has been proven on hundreds of projects throughout our over 50 years of cumulative experience. For example, When Lee County Water Supply Corporation’s (LCWSC) Country Corners well experienced water quality issues, including color, turbidity, and high iron concentrations, the entire well was profiled to a depth of 1,840 feet below ground surface (bgs) in just two days. Based on the profiling results, we recommended that a packer and engineered suction be installed to isolate the upper and lower screens. After implementing our proposed solution, the well was brought back into production, the water quality issues were resolved, and LCWSC avoided some $2.3 million in costs for a replacement well.

A similar example occurred in Riesel, Texas, where a cooling water well did not meet water quality requirements for both TDS and sulfate concentrations. we profiled the well to define the production and water quality for each perforated interval. After identifying a new fresh water quality zone through correlating profiling data with the electric log and perforating the casing in this new zone, the water quality met standards and $1.5 million in replacement well costs were avoided.

Our people, our commitment, and the solutions we deliver are what differentiate INTERA from other consulting firms. At INTERA, we work diligently every day to achieve our vision of Delivering Excellence with Every Solution. Contact us to learn more.